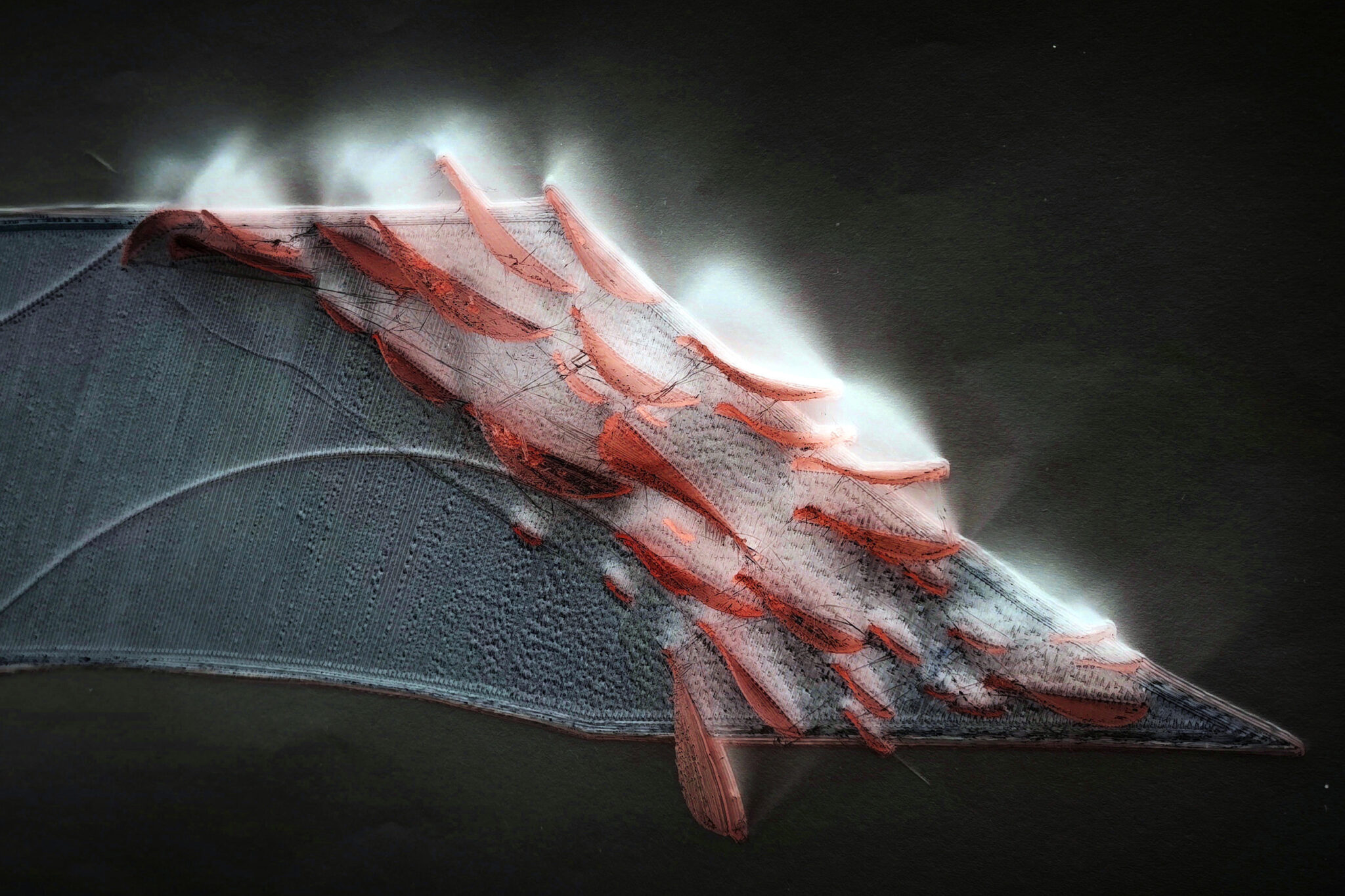

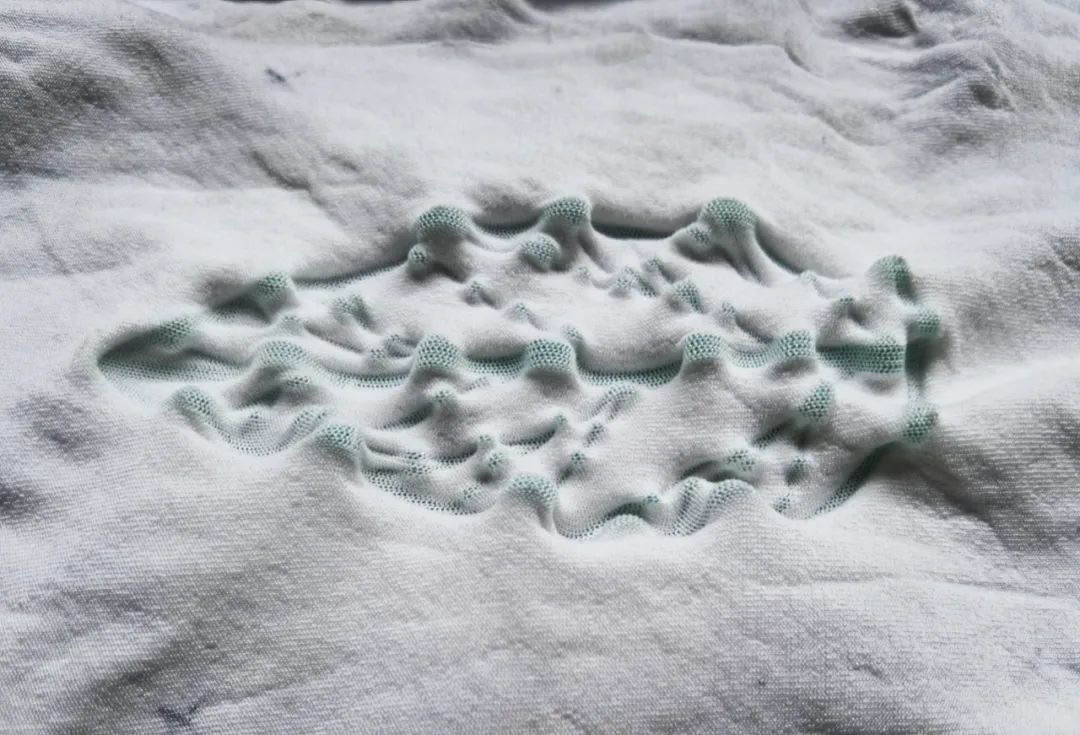

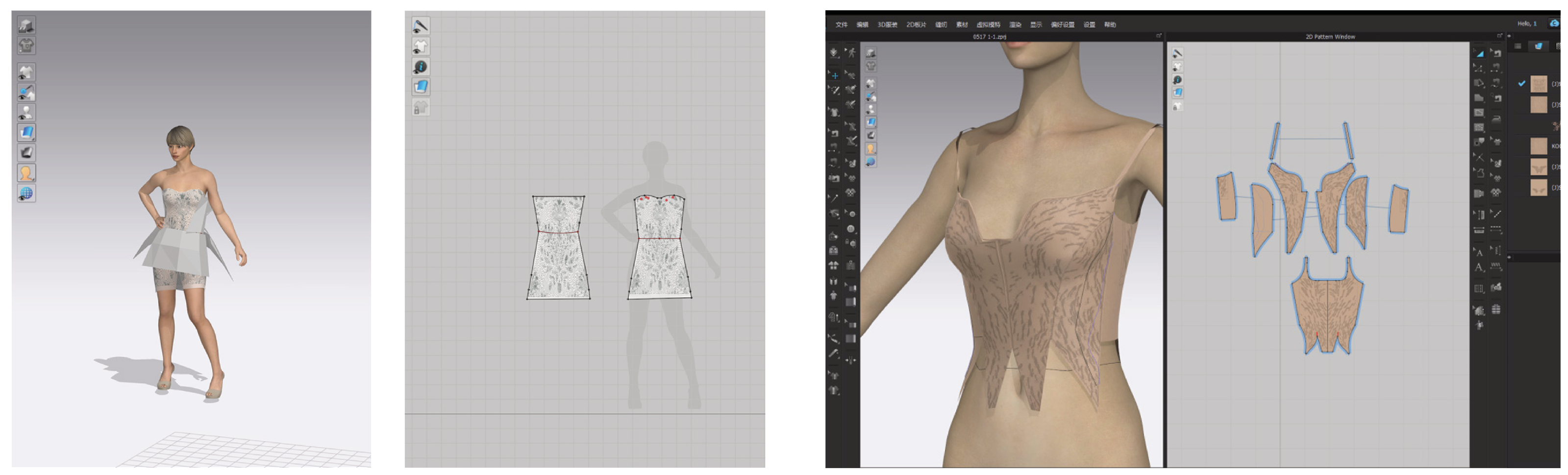

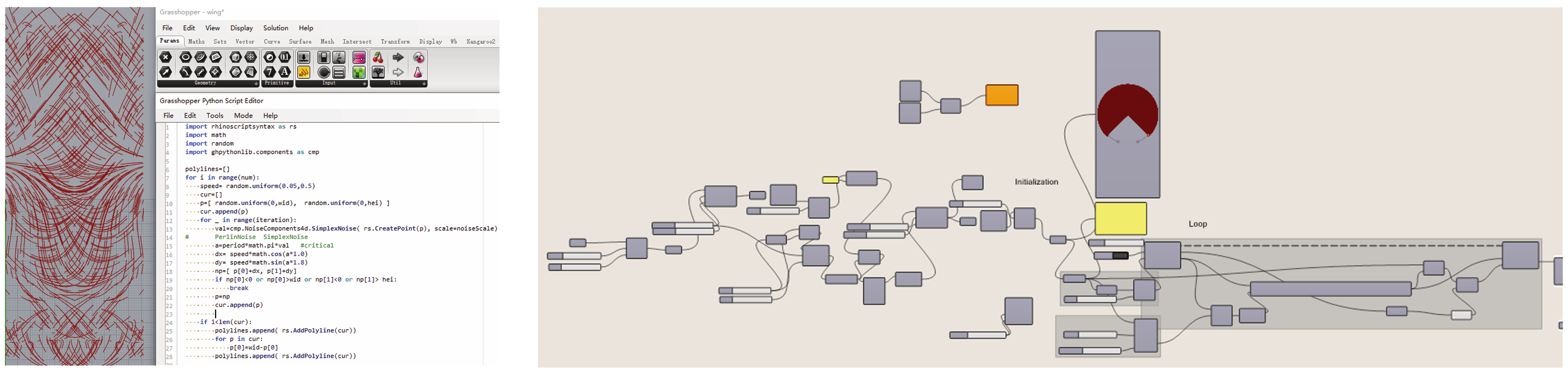

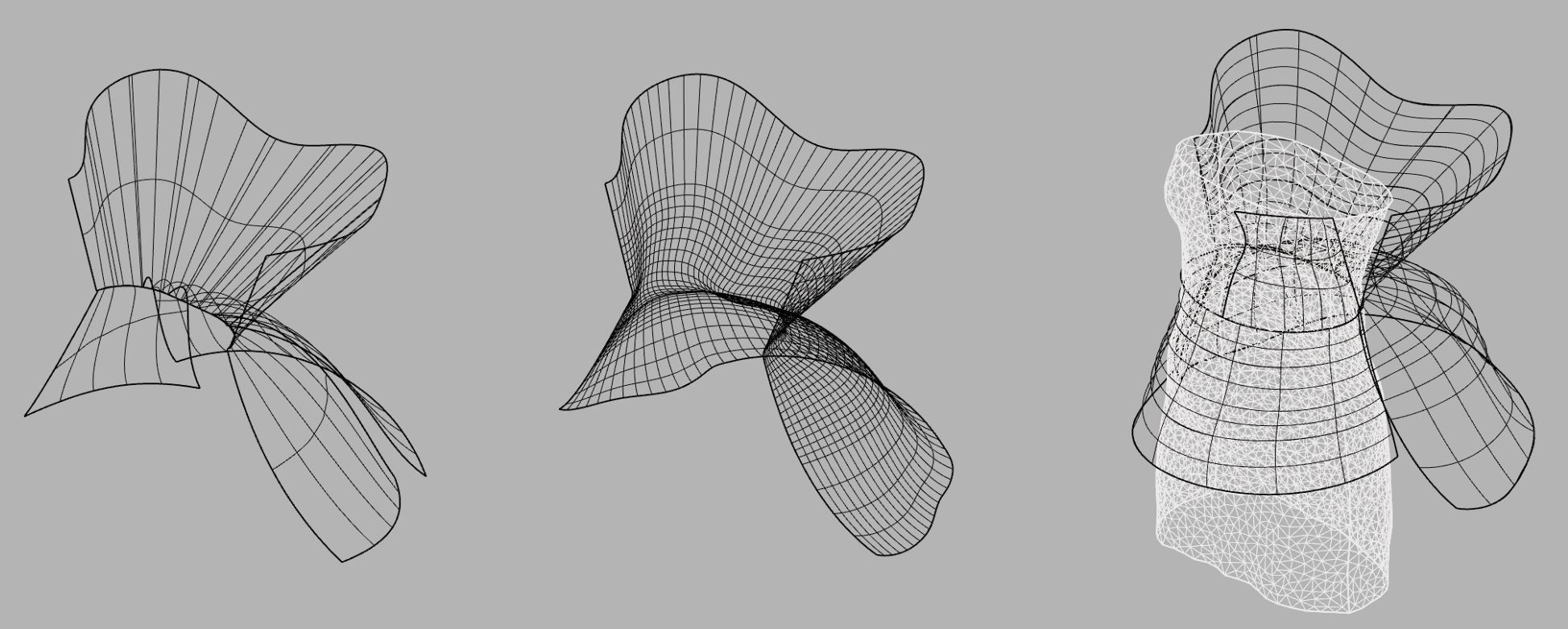

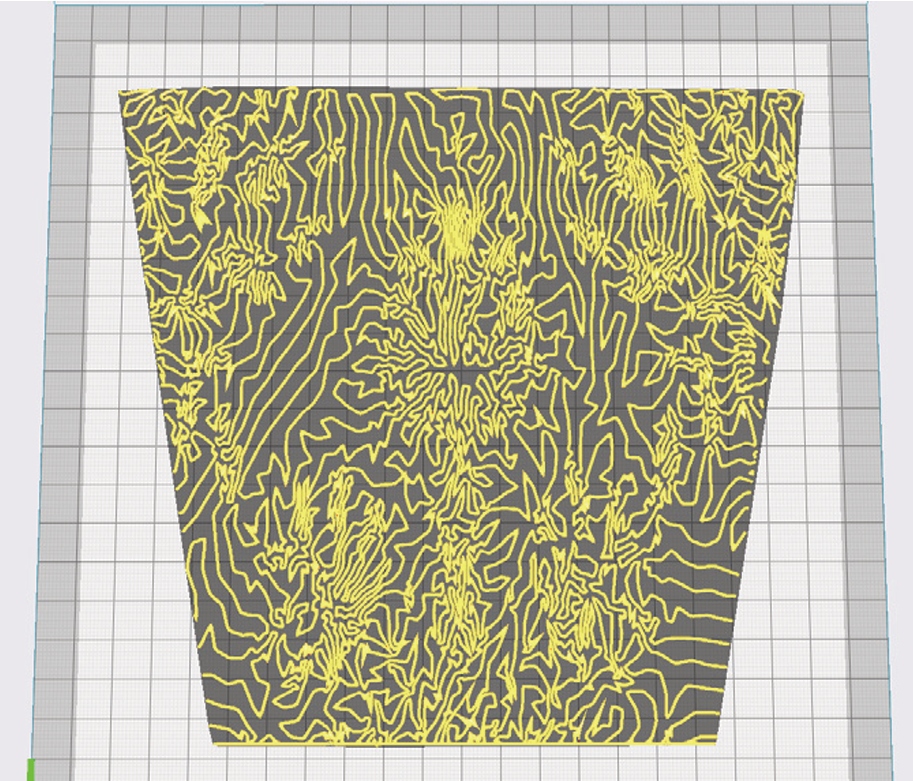

Emerging 3D printing technologies are forging unprecedented new types of fabrics, serving as a significant impetus for architects to engage in custom fashion design. Notably, the use of TPU flexible printing and FDM combined with fabric introduces novel possibilities for fashion silhouette and fabric texture. Many fabric printing experiments encounter failures or flaws, yet direct interaction with the fabric using hands or body allows for adjustments in its geometric structure or printing technique.

Designers strive to produce fabrics that meet predefined characteristics, but the iterative process of experimentation can also lead to entirely new ideas. Thus, design research and manufacturing experiments complement each other. The development of 3D fabrics based on computational design spans across architecture, fashion design, information technology, and automation technology. It also integrates cultural ethos, artistic sentiment, mathematical logic, and practical techniques. This development of 3D fabrics will become an intrinsic part of fashion design practices.

This project focuses on customized 3D printing techniques for garments, exploring how fabrics can effectively integrate with various materials to form complex self-forming mechanisms. It involves digital adjustment of the fabric's texture, performance, and appearance, innovating fashion design through customized processes.